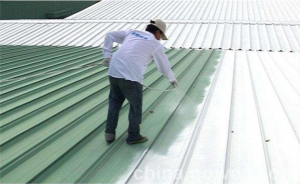

Water-based acrylic thermal insulation and anti-corrosion paint

Product performance

With excellent weather resistance, UV resistance and self-cleaning function;

Excellent near-infrared and visible light reflection properties, used in conjunction with thermal insulation primers to provide excellent thermal insulation effects; excellent acid resistance, salt water resistance, salt spray resistance, and wide applicability.

Application range

It is suitable for metal products such as chemical oil storage tanks, metal workshops, locomotive carriages, metal pipes and other metal products that have both thermal insulation requirements and high anti-corrosion requirements.

Recommended packages

FL-108D water-based acrylic primer 2 times

FL-205 Water-based acrylic thermal insulation paint 2-3 times It is recommended that the total dry film thickness of the package should not be less than 500μm.

Storage and Transportation

Surface treatment: The performance of the paint is usually proportional to the degree of surface treatment. When painting on the matching paint, the surface is required to be clean and dry, free of impurities such as oil and dust. It must be stirred evenly before construction. If the viscosity is too large, it can be diluted with clean water to the construction viscosity. In order to ensure the quality of the paint film, we recommend that the amount of water added is 0%-5% of the original paint weight. Multi-pass construction is adopted, and the subsequent coating must be carried out after the surface of the previous paint film is dry. The relative humidity is less than 85%, and the construction surface temperature is greater than 10°C and greater than the dew point temperature by 3°C. Rain, snow and weather cannot be used outdoors. If construction has already been carried out, the paint film can be protected by covering it with a tarpaulin.

Executive standard

HG/T5176-2017 GB/T50393-2017

Supporting construction technical parameters

| Gloss | Matte |

| color | White |

| Volume solid content | 40%±2 |

| Theoretical coating rate | about 2m²/L (based on 200μm dry film) |

| Specific gravity | about 1.25 Kg/L |

| Surface dry | ≤30min(25℃) |

| Hard work | ≤24h (25℃) |

| Recoating time | minimum 4h, maximum 48h (25℃) |

| Insulation temperature difference | ≥10℃ |