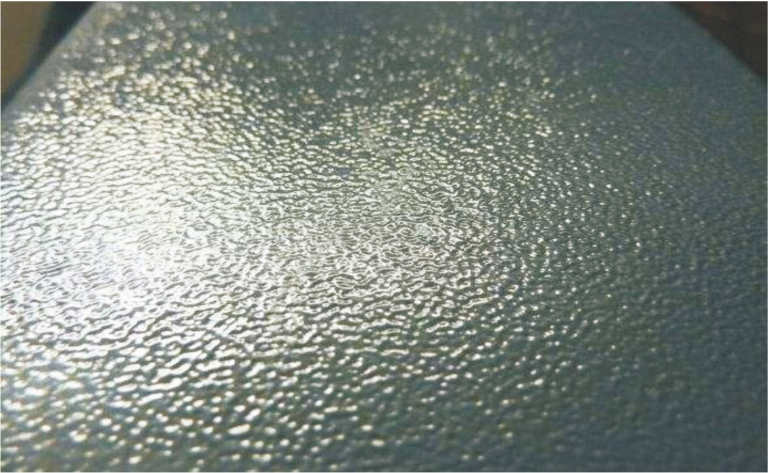

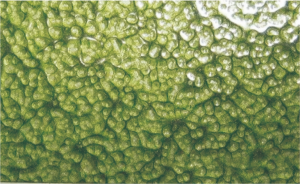

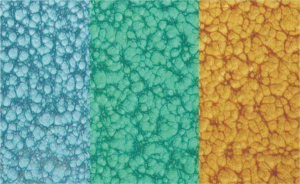

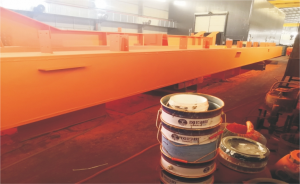

Water-based hammer pattern corrugated orange pattern paint series

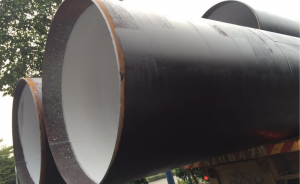

Scope of application

It is suitable for surface coating of various indoor and outdoor metal equipment, and is specially used for anti-corrosion protection and decoration of metal surfaces such as mechanical and electrical equipment, aircraft, instruments, electric fans, toys, bicycles, and auto parts.

surface treatment

All surfaces to be coated should be free of oil and dust, and should be kept clean, dry, and pollution-free. The old paint film must be completely dissolved by thinner, and primers and putty should not be sprayed to cover. All surfaces should be evaluated and treated according to ISO8504:1992.

Construction Instructions

(1) The coating should be fully stirred and evenly mixed; the bottom and surface curing agents must be used correctly and the proportion must be accurate;

(2) The mechanical paint requires one-time film thickness. To achieve a better gloss, it is best to use an air-assisted airless type with relatively good atomization.

spray, or require multiple sprays.

(3) The paint film can be dried by itself or at low temperature, the hardness of the dried paint film is higher, and the effect of corrugated hammer pattern is better;

(4) Epoxy or polyurethane can be selected for indoor equipment, and polyurethane must be used for outdoor equipment;

(5) After spraying, the tools must be cleaned with diluent in time, otherwise the spray gun can no longer be used.

Recommended package

Primer FL-213D/Water-based epoxy primer 1 time

Topcoat FL-133M water-based polyurethane topcoat (corrugated/hammer pattern/orange pattern)/213M water-based epoxy topcoat (corrugated/hammer pattern/orange pattern) 1-2 times, the matching thickness is not less than 150um.

Executive standard: HG/T5176-2017

Supporting construction technical parameters

| Gloss | High gloss (top coat) |

| Color | refer to the wind chime tree color card or according to the sample |

| Volume solid content | 40%±2 |

| Theoretical coating rate | 8m²/L (dry film 50 microns) |

| Specific gravity | primer 1.3kg/L, topcoat 1.15kg/L |

| Surface dry (50% humidity) | 15℃≤2h, 25℃≤1h, 35℃≤0.5h |

| Hard working (humidity 50%) | 15℃≤12h, 25℃≤8h, 35℃≤5h |

| Recoating time | recommended minimum 24h; maximum unlimited (25℃) |

| Complete curing | 7d (25℃) |

| Hardness | 1-2H |

| Adhesion | Grade 1 |

| Shock resistance | 50kg.cm |

| Mixed use period | 4h (25℃) |