Water-based steel structure alkyd anti-corrosion paint

Product performance

This product series is prepared with water-based alkyd functional resin, non-toxic and environmentally friendly anti-rust pigments, and no organic solvent is added.

Application range

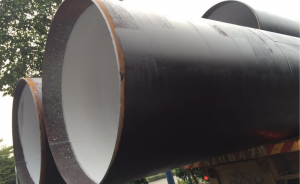

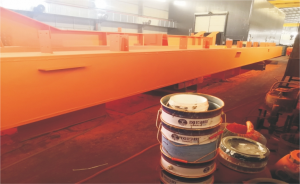

It is suitable for various large-scale steel structures, mechanical equipment, guardrail pipelines, cast iron parts, oil tanks, petrochemical oil pipelines and external anti-corrosion devices with harsh environments and high anti-corrosion performance requirements. It can be used as a primer for various solvent-based anti-corrosion coatings and other industrial paints for metal base layers.

Construction Description

Finish: New Steel: Sandblasted to Sa2 level. For temporary surface protection, apply an appropriate shop primer. For other surfaces: Remove grease with a cleaning agent, and remove salt and other contaminants with high-pressure fresh water. Remove rust and loose coating with sandblasting and power tools.

Construction conditions: The construction should be carried out according to the best construction conditions required by normal requirements, and a large amount of ventilation should be carried out during construction and drying in a narrow space. It can be mixed, brushed and sprayed. High pressure airless spraying is recommended to obtain a uniform and good coating film. It must be stirred evenly before construction. If the viscosity is too large, it can be diluted with 5%-10% of the original paint weight with clean water to the construction viscosity. The relative humidity is less than 85%, and the construction surface temperature is greater than 0°C and greater than the dew point temperature by 3°C.

Recommended packages

FL-1001D 1-2 times water-based alkyd primer 1-2 times

FL-1001M 1-2 times is recommended that the total dry film thickness of the package is not less than 150um.

Storage and Packaging

Storage temperature ≥0℃, packing 20±0.1kg Executive standard: HG/T5176-2017

Supporting construction technical parameters

| Gloss | Primer matte, topcoat glossy |

| Color | primer iron red, black, gray, topcoat refer to the national standard color card of bell tree |

| Volume solid content | 40%±2 |

| Theoretical coating rate | 8m²/L (dry film 50 microns) |

| Specific gravity | primer 1.25kg/L, topcoat 1.20kg/L |

| Surface dry (humidity 60%) | 15℃≤1h, 25℃≤0.5h, 35℃≤0.1h |

| Hard working (humidity 60%) | 15℃≤10h, 25℃≤5h, 35℃≤3h |

| Recoating time | dry to the touch |

| Adhesion | Grade 1 |

| Shock resistance | 50kg.cm |

Product packaging