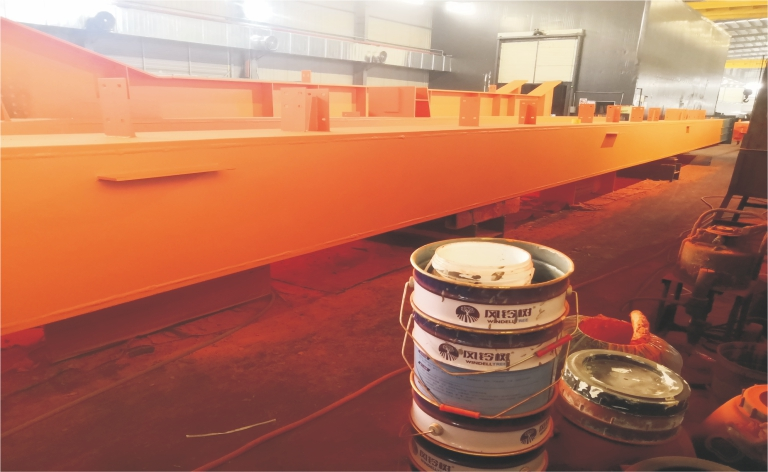

Waterborne steel structure epoxy paint series

Product performance

Good anti-corrosion ability, good adaptability between primer, middle coat and top coat;

Using water as the dispersion medium, no toxic and harmful substances are produced during the construction process and the coating film forming process, which meets the requirements of environmental protection; two-component curing, good hardness, good adhesion, excellent chemical resistance; good aging resistance, not easy to brittle; The compatibility is good, the coating film is firmly attached to the metal substrate, and the thickness and fullness of the coating film can be enhanced.

Application range

It is suitable for various large-scale indoor steel structures, especially for chemical workshops and other highly corrosive environments.

Surface treatment

Remove oil, grease, etc. with a suitable cleaning agent. This product must be applied on the base coat, and the base material is free of oil and dust.

Construction Description

It can be applied by roller, brush and spray. High pressure airless spray is recommended to obtain a uniform and good coating film.

The ratio of main paint and curing agent: 1:0.1. Before construction, the main paint must be stirred evenly, and the curing agent must be added according to the ratio. It is recommended to use an electric mixer to stir for 3 minutes. . If the viscosity is too thick, it can be diluted with clean water to the construction viscosity. In order to ensure the quality of the paint film, we recommend that the amount of water added is 5%-10% of the original paint weight. Multi-pass construction is adopted, and the subsequent coating must be carried out after the surface of the previous paint film is dry. The relative humidity is less than 85%, and the construction surface temperature is greater than 10°C and greater than the dew point temperature by 3°C. Rain, snow and weather cannot be used outdoors. If it has been constructed, the paint film can be protected by covering it with a tarp.

Recommended packages

Primer FL-123D water-based epoxy primer 1 time

Intermediate paint FL-123Z water-based epoxy micaceous iron intermediate paint 1 time

Topcoat FL-123M water-based epoxy topcoat 1 time, matching thickness not less than 200μm

Executive standard

HG/T5176-2017

Supporting construction technical parameters

| Gloss | Primer, midcoat flat, topcoat glossy |

| Color | The primer and middle paint are usually gray, iron red, black, and the top paint refers to the national standard color card of the bell tree |

| Volume solid content | primer 40%±2, intermediate coat 50%±2, top coat 40%±2 |

| Theoretical coating rate | primer, topcoat 5m²/L (dry film 80 microns), intermediate paint 5m²/L (dry film 100 microns) |

| Specific gravity | primer 1.30 kg/L, intermediate paint 1.50 kg/L, top coat 1.20 kg/L |

| Adhesion | Grade 1 |

| Shock resistance | 50kg.cm |

| Surface dry (humidity 50%) | 15℃≤5h, 25℃≤3h, 35℃≤1.5h |

| Hard working (humidity 50%) | 15℃≤24h, 25℃≤15h, 35℃≤8h |

| Recoating time | recommended minimum 6h; maximum 48h (25°C) |

| Mixed use period | 6h (25℃) |

| Complete curing | 7d (25℃) |

Product packaging